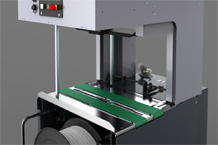

Products / Product catalog / SMB ONO

Equipment

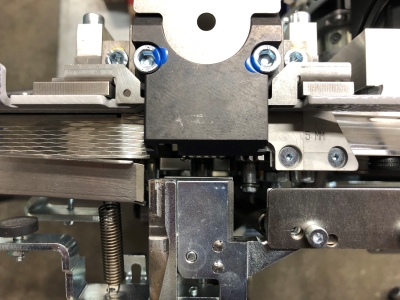

- ASLF 'Anti-Strap-Loss-Function' Constant strap control

- Automatic Strap feed

- DAT 'Direct-Access-Technology'

- The exclusive eject function avoids strap jam

- Torque controlled strap tension, adjustable

- GreenTech energy concept, low power consumption

- Intuitive operator interface

- Machine movable

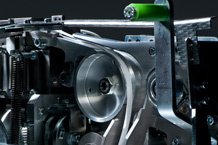

- MFT 'Mono-Frame-Technology'

- Table height steplessly adjustable

- Wear-free, energy saving direct-drive-motors

- Low maintenance and low wear strap arch

- Many specific options available, easily configurable

TECHNICAL SPECIFICATION

CAPACITY

Single strap, bundles/minute up to

20-40

Depending on arch size and tension force

Without bundle press

BUNDLES

Circular products

Inside diameter min. in mm

200

Outside diameter in mm

1300

Circular Width in mm

min. 55

Free height

max. 630

STRAP TENSION

Adjustable with 10 steps

Automatic strap tensioning

Tension at bundle in N

max. 600

Tension path in mm

max.

STRAPPING MATERIAL

Polypropylene DIN EN 13 394

Width in mm

9 - 12

Thickness in mm

0.4 - 0.65

SEALING METHOD

Heat seal. Tensile strength of welded joint is approx. 80% of the breaking strength of the strap

STRAP COIL

Core ID in mm

200

Core OD in mm

420

Width in mm

190 (160,180,200)

POWER SUPPLY

Wide Range Input 100-240V, 1AC; 47-63 Hz

optional

Wide Range Input 380-520V, 3AC; 47 63 Hz

Maximum fusing 16A (B-character)

Protection Type

IP 22

POWER CONSUMPTION

Power consumption in kW approx.

0,30

WEIGHT

Total weight approx. in kg

250

OPERATING CONDITIONS

Temperature range in °C [°F]

5 - 45