Products / Product catalog / SMB CUBE-plus

Equipment

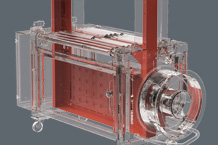

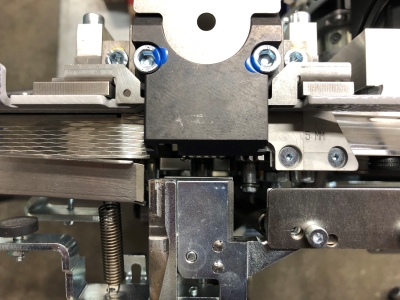

- ASLF 'Anti-Strap-Loss-Function' Constant strap control

- Automatic Strap feed

- Strap width 9 or 12 mm

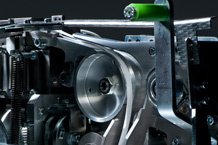

- DAT 'Direct-Access-Technology'

- The exclusive eject function avoids strap jam

- Torque controlled strap tension, adjustable

- Upstream and downstream interlocks

- ETS 'Easy to Service' - Maintenance while production

- Conveyor speed steplessly adjustable

- GreenTech energy concept, low power consumption

- Intuitive operator interface

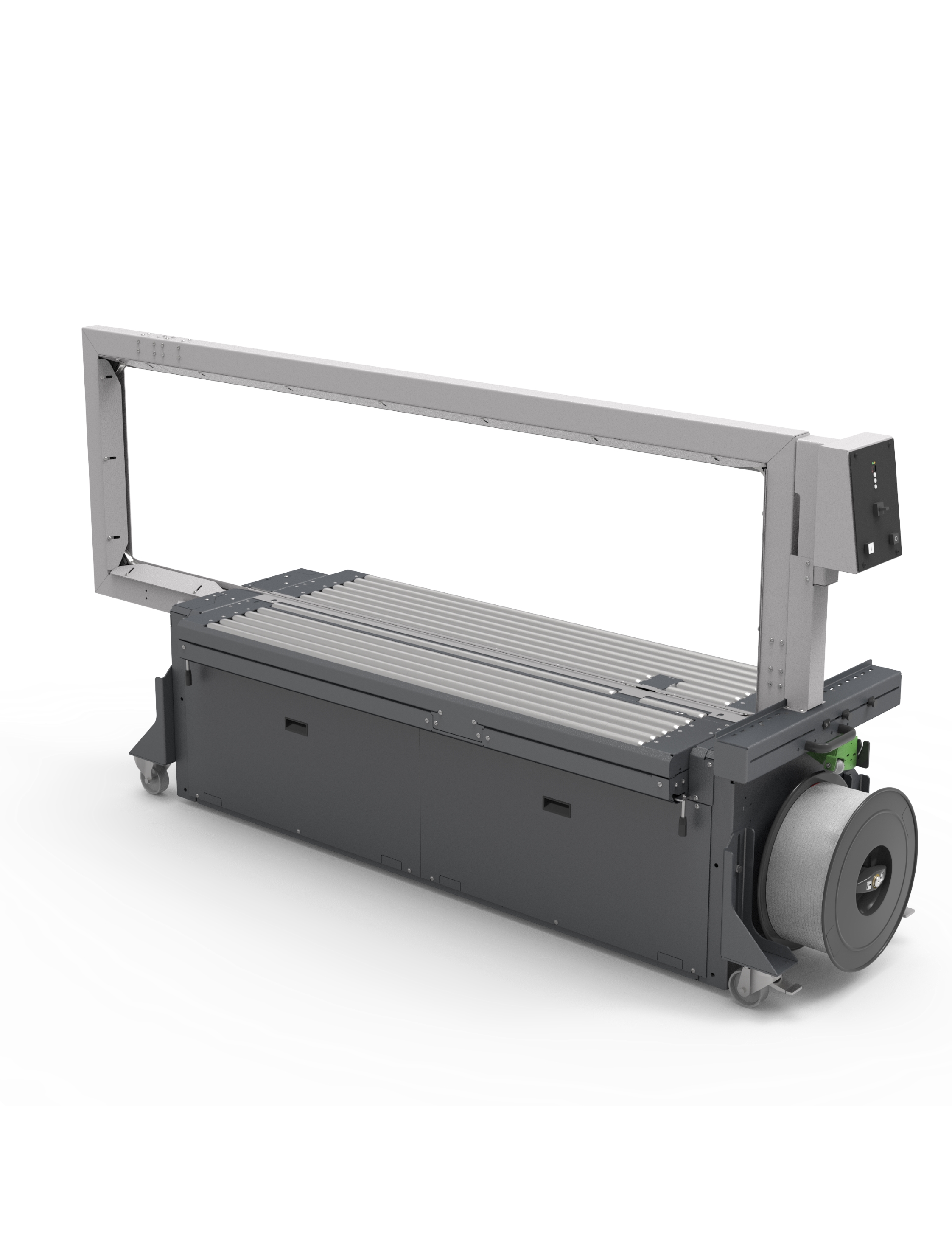

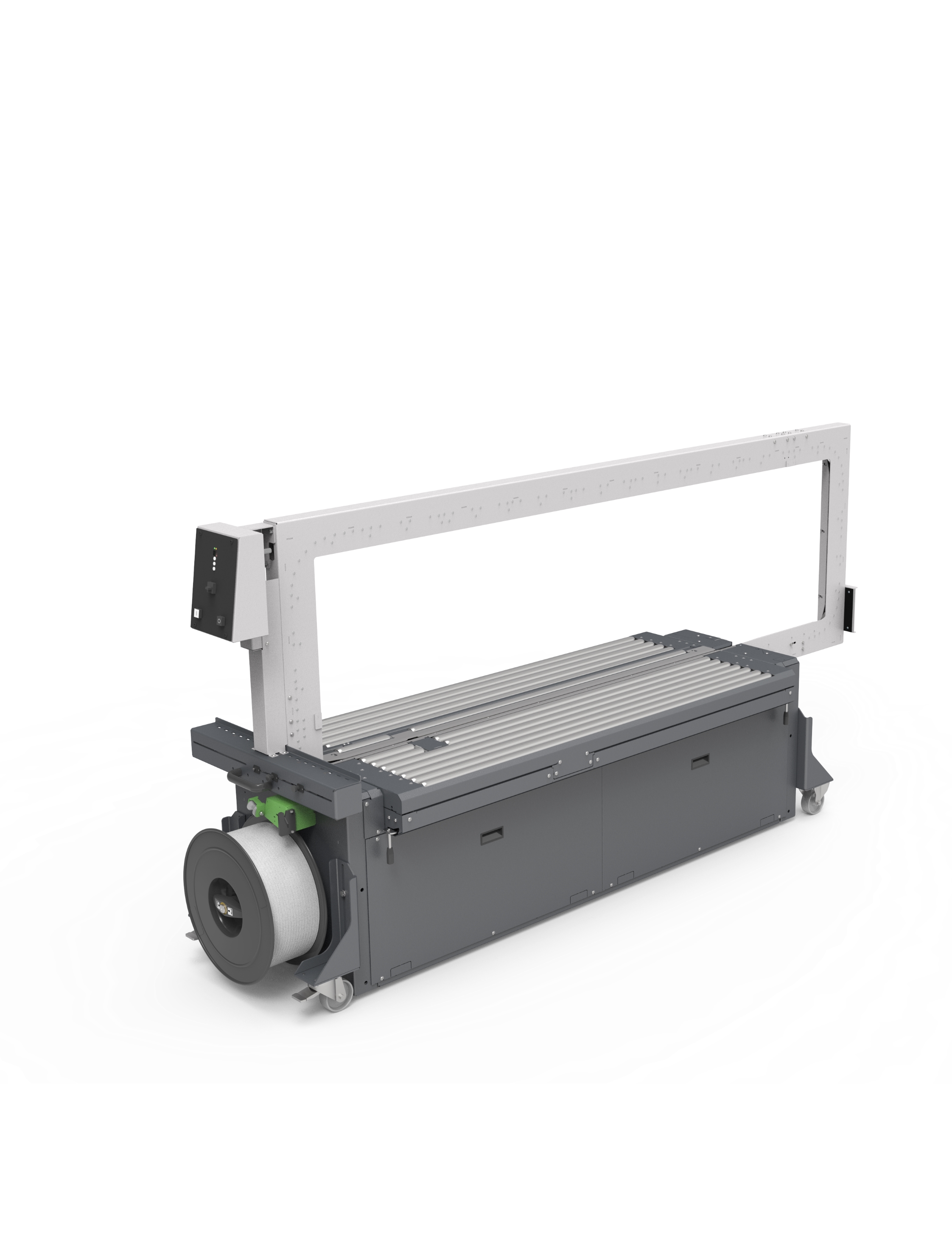

- Machine movable

- SAO 'Safe and Open' - Safe without protection doors

- Table height steplessly adjustable

- Bundle flow control

- Wear-free, energy saving direct-drive-motors

- Low maintenance and low wear strap arch

- Many specific options available, easily configurable

A table of dimensions can be found in the data sheets for the machine. Alternatively, you can view this website on a desktop browser and receive the dimensions table at this point.

Arch Size WxH

Arch Size WxH

mmArch Size WxH

2250x600Arch Size WxH

2650x600Sealing head off-centered

Sealing head off-centered

Sealing head off-centered

Sealing head off-centered

Machine width

Machine width

GMachine width

2975Machine width

3325Total height

Total height

FTotal height

1420-1505Total height

1420-1505Arch width

Arch width

AArch width

2450Arch width

2800Inner height (arch)

Inner height (arch)

CInner height (arch)

640Inner height (arch)

640Position sealing head

Position sealing head

BPosition sealing head

353Position sealing head

353Weight in kg

Weight in kg

Weight in kg

475Weight in kg

485max. bundle width

max. bundle width

max. bundle width

2250max. bundle width

2650max. bundle height

max. bundle height

max. bundle height

600max. bundle height

600TECHNICAL SPECIFICATION

CAPACITY

Single strap, bundles/minute up to

max. 20

At table belt speed in m/s

0.8

Based on bundle size l x w in mm

300 x 210

Depending on arch size and tension force

BUNDLES

Width in mm

Min.

120

Max. bundle width depending on arch size

Length in mm

min. 180

Height in mm

Min.

20

Max. bundle height depending on arch size

Weight in kg

max. 100

TRANSPORT SPEED

m/s

0,20 - 1,00

STRAP TENSION

Adjustable with 10 steps

Automatic strap tensioning

Tension at bundle in N

max. 450

Tension path in mm

max.

STRAPPING MATERIAL

Polypropylene DIN EN 13 394

Width in mm

9 - 12

Thickness in mm

0.55 - 0.65

SEALING METHOD

Heat seal. Tensile strength of welded joint is approx. 80% of the breaking strength of the strap

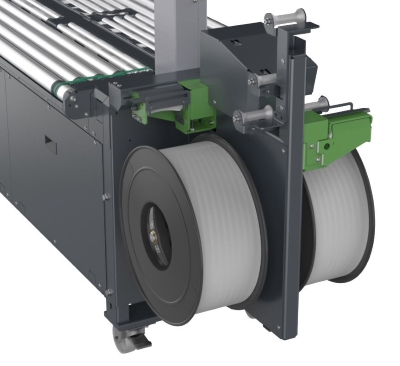

STRAP COIL

Core ID in mm

200-228

Core OD in mm

420

Width in mm

160 - 190

POWER SUPPLY

Wide Range Input 100-240V, 1AC; 47-63 Hz

Wide Range Input 380-520V, 3AC; 47 63 Hz

optional

Maximum fusing 16A (B-character)

Protection Type

IP22

POWER CONSUMPTION

Power consumption in kW approx.

0,30

OPERATING CONDITIONS

Temperature range in °C [°F]

5 - 45