Products / Product catalog / SMB START

Equipment

- ASLF 'Anti-Strap-Loss-Function' Constant strap control

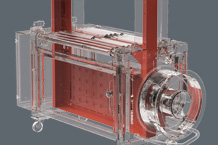

- Strap width 5 - 9 mm, adjustable

- Automatic strap threading, soft

- Strap end detection system with automatic discharge of remaining strap

- Automatic strap tensioning, stepless

- Strap coil detection with yellow indicator lamp

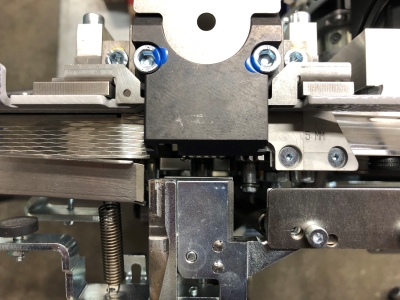

- DAT 'Direct-Access-Technology'

- The exclusive eject function avoids strap jam

- Torque controlled strap tension, adjustable

- Upstream and downstream interlocks with complete plug connection

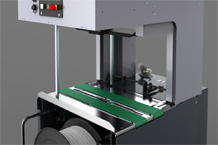

- Conveyor speed steplessly adjustable

- GreenTech energy concept, low power consumption

- Bundle stops in longitudinal machine, optional

- Bundle press, optional

- Production data analysis via Ethernet/USB

- SAO 'Safe and Open' - Safe without protection doors

- SMART TOUCH – Icon control concept

- Standby mode

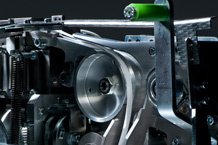

- Wear-free, energy saving direct-drive-motors

- Wear-free Strap-frame by stainless steel guide

- Many specific options available, easily configurable

TECHNICAL SPECIFICATION

CAPACITY

Cross strap, bundles/minute

32

At table belt speed in m/s

1

Based on bundle size l x w in mm

300 x 210

Depending on tension force

BUNDLES

Width in mm

150 - 420

Length in mm

150 - 420

Height in mm

10 - 400

Weight in kg

max. 25

TRANSPORT SPEED

m/s

0,20 - 1,00

STRAP TENSION

Steplessly adjustable

Automatic strap tensioning, stepless, depending on height of bundle

Tension at bundle in N

max. 325

Tension path in mm

max. 200

STRAPPING MATERIAL

Polypropylene DIN EN 13 394

Width in mm

5 - 9

Thickness in mm

0.4 - 0.55

SEALING METHOD

Heat seal. Tensile strength of welded joint is approx. 80% of the breaking strength of the strap

STRAP COIL

Core ID in mm

200

Core OD in mm

420

Width in mm

190 (160,180,200)

POWER SUPPLY

Wide Range Input 380-520V, 3AC; 47 63 Hz

Maximum fusing 16A (B-character)

Protection Type

IP 54

POWER CONSUMPTION

Power consumption in kW approx.

0,70

WEIGHT

Total weight approx. in kg

780

OPERATING CONDITIONS

Temperature range in °C [°F]

5 - 45