Products / Product catalog / SMB COR-flex

Equipment

- 5000 bundle recipes

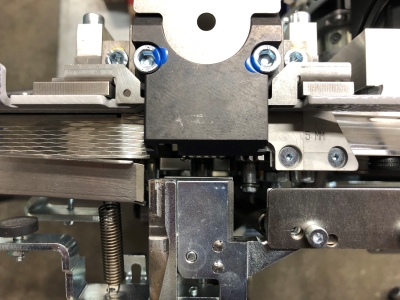

- ASLF 'Anti-Strap-Loss-Function' Constant strap control

- Strap width 5 - 12 mm / 28mm, either

- Strap end detection system with automatic discharge of remaining strap

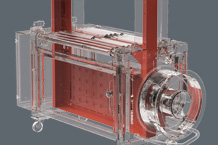

- DAT 'Direct-Access-Technology'

- EPP 'Exact Product Path'

- GreenTech energy concept, low power consumption

- OPTIONAL:Bundle stop plate for second strap

- OPTIONAL: Bundle compensator backside

- OPTIONAL: Narrow products, min. package width 95 mm

- OPTIONAL: Fully automatic format adjustment, format change in 30 seconds

- Bundle stop plate with pre-positioning, no contact with bundle when clearing the bundle, with quick adjustment

- Bundle press, pre-positioning and electric driven

- Production data analysis via Ethernet/USB

- SMART TOUCH 4.0 – Icon control concept

- Low maintenance and low wear strap arch

- Many specific options available, easily configurable

- Safe alignment also of solid board and thin corrugated board

- Preparation for network access and remote maintenance access via VPN

A table of dimensions can be found in the data sheets for the machine. Alternatively, you can view this website on a desktop browser and receive the dimensions table at this point.

Arch Size WxH

Arch Size WxH

mmArch Size WxH

850x340Arch Size WxH

1250x340Sealing head centered

Sealing head centered

Sealing head centered

Sealing head centered

Order number

Order number

Order number

x56358Order number

x57825Machine width

Machine width

GMachine width

1410Machine width

1810Total height

Total height

HTotal height

2110-2300Total height

2110-2300Table height

Table height

DTable height

820-1010Table height

820-1010Table height with casters

Table height with casters

Table height with casters

910Table height with casters

910Weight in kg

Weight in kg

Weight in kg

ca. 1250Weight in kg

ca. 1450bundle width

bundle width

Abundle width

130-850bundle width

130-1250max. bundle height

max. bundle height

Bmax. bundle height

340max. bundle height

340Additional space needed

Additional space needed

FS/FBAdditional space needed

1050/1500Additional space needed

1250/1700Distance bundle stop

Distance bundle stop

CDistance bundle stop

25-580Distance bundle stop

25-580Total width + Coil

Total width + Coil

JTotal width + Coil

1650Total width + Coil

2050TECHNICAL SPECIFICATION

CAPACITY

Single strap, bundles/minute up to

B max.17 / S max. 32

Parallel strap, bundles/minute

B max.12 / S max. 21

At table belt speed in m/s

1.4

Based on bundle size l x w x h in mm

300 x 210 x 150

Depending on arch size and tension force

BUNDLES

Width in mm

max.

Length in mm

min. 180

Height in mm

min. 50

Weight in kg

max. 20

TRANSPORT SPEED

m/s

0,40 - 1,40

STRAP TENSION

Adjustable with 10 steps

Tension at bundle in N

max. 400

Tension path in mm

max.

STRAPPING MATERIAL

Polypropylene DIN EN 13 394

Width in mm

5 - 12

Thickness in mm

0.35 - 0.65

BANDEROLE

Polypropylene

Width in mm

28 - 28

Thickness in μm

50 - 50

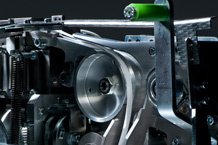

SEALING METHOD

Heat seal. Tensile strength of welded joint is approx. 80% of the breaking strength of the strap

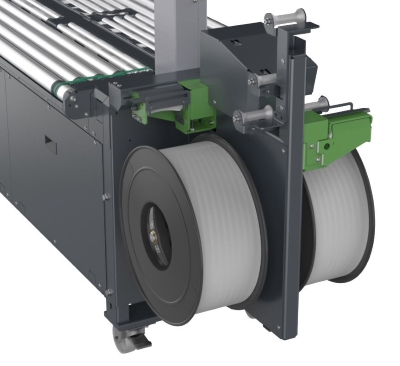

STRAP COIL

Core ID in mm

B 76 / S 200

Core OD in mm

B 500 / S 420

Width in mm

B 28 / S 190

POWER SUPPLY

Wide Range Input 380-520V, 3AC/N; 47 63 Hz

Maximum fusing 16A (B-character)

Protection Type

IP 54

POWER CONSUMPTION

Power consumption in kW approx.

0,98

PNEUMATICS

Operating pressure in bar

6

Air consumption per cycle in l (free air)

4.2

OPERATING CONDITIONS

Temperature range in °C [°F]

5 - 45